INDUSTRIAL ADDITIVE MANUFACTURING CHANGES EVERYTHING

Why is IAM revolutionizing the future of production?

IAM is the answer to an increasingly complex, fast moving world that demands more flexibility. The very best of two great worlds is combined in IAM, the creative freedom of additive manufacturing and efficient effectiveness of industrial manufacturing. Industrial Additive Manufacturing is the key to highest flexibility, quality and volume.

CREATIVE FREEDOM ONLY IAM CAN PROVIDE

I am flexible for just in time needs

Absolute freedom in design and quantity. Design and modification freedom, tool-less shaping, unlimited variability in quantities, high-performance production and delivery times in new dimensions. Weisser produces your products following the most flexible specifications. That is additive manufacturing at its best. That means transforming ideas into products without restrictions.

STANDARDIZED PROCESS ALL THE WAY THROUGH

I am serious in securing continuous quality

Series production has its own rules. IAM produces your parts to exactly these specifications. Outstanding materials meet the established manufacturing processes. Biocompatibility, heat resistance and flame resistance. A new high performance manufacturing process provides industrial known quality, process stability and efficiency. Combined we´re able to produce end-use parts, fully usable series components and technical functional component: Up to 10 million parts a year.

OUTSTANDING MATERIALS & SYSTEMS

I am the Key for IAM

For additive serial production of high-precision plastic parts with outstanding mechanical properties, a special technology is required.

We´re using the Hot Lithography technology which transforms the highly viscous photopolymers into a processable state using patented technology.

A 3D model is built up layer by layer in slices of 50-100 µm. The transformation of the material from liquid to solid and therefore the manifestation of the digital model is done by light.

In a digitized process chain, you can perform production or product changes at any time - without significant additional costs and in a fraction of the time.

In order to be able to produce not only excellent components, but excellent components in quantities of millions, we own scalable systems with construction areas of 1000x280 mm.

The fully digital serial production of complex, thermo-mechanically stable and precise components paves the way for the agile production of the future.

That is IAM.

100 YEARS’ EXPERIENCE COMBINED WITH IAM

I am well experienced in new technologies

400 Million Parts per year are shipped from the production site in the heart of Germany to the entire world.

With 100 years experience in industrial production, we transform your ideas into trustworthy, reliable and outstanding functional prototypes or serial end-use parts.

Without limitations in design, quantity and materials.

As a functional prototype to significantly reduce development costs and times or as an end-use part to be able to design and produce in the most flexible way.

We enable future in a customer centric and solution orientated way since 100 years.

R&D BOOSTER

I am a functional prototype

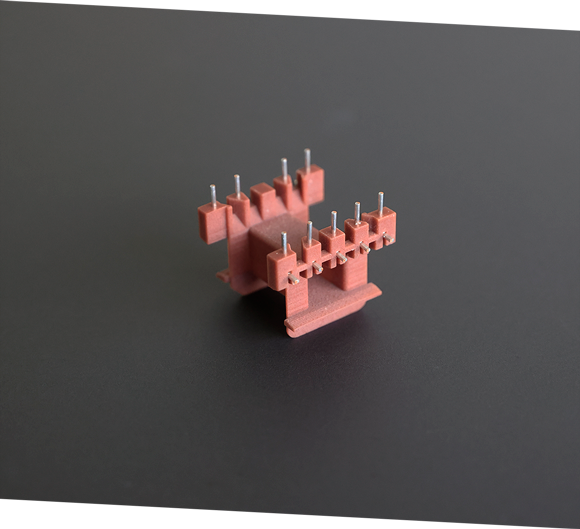

In this case our customer needed a modification of one of our standard coilformers for the electronic industry to validate a new product. Since this involved not only form-technical but also functional changes, tests had to be performed with the new design. For this purpose the Coilformer was printed and assembled with contacts. Thus, the customer was able to complete his development in the shortest possible time as well as investing in an expensive tool.

Weisser your R&D Booster

FLEXIBLE SERIES PRODUCTION

I am a series part

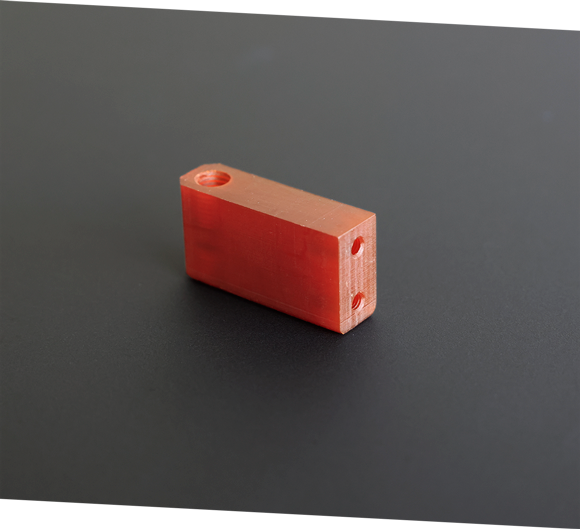

In this case, the customer required a part for the medical industry. Several hundred components per month, with batch sizes that are unclear and likely to be very variable. It quickly became clear that a possible injection molding tool would be disproportionately expensive due to the small quantities. With scalable IAM systems and high-performance materials, we can produce as many parts as you want, whenever you want. If the part design changes (as it did in this case), you can simply create and print a new 3D-model from one day to the next, giving you instant flexibility in shape and quantity with high end materials, printing high-performance end-use parts.

Hannover Messe – 7. Additive Manufacturing Symposium

Welchen Beitrag leistet die Additive Fertigung für die Elektroindustrie?'

Beim Vortrag "AM für die spezifischen Anforderungen der elektrischen…

Pioneers of additive manufacturing reflect on a year of growth and set future goals on the 3D-Industrie Podcast

In a recent episode of Germany's leading podcast on additive manufacturing, Alexander and Max returned to discuss their year-long journey in additive…

LEADING IN TECHNICAL PLASTIC PARTS

I am a Company with future tradition

For over 60 years Weisser Spulenkörper is a market-leading company in the production of bobbins, boxes and insulation parts for magnets, motors, relays, sensors and transformers.

Weisser leaves nothing to be desired and – due to latest technology – we are able to continuously develop and offer innovative solutions for extremely high requirements in a customer centric way.

Founded in 1922, 100 years later Weisser employs more than 200 people at its headquarters in Neresheim, Germany and offers a product range from more than 4500 articles made from more than 100 materials.

Whether you need standardized catalogue products or individual customer products, standard or precision injection-molded parts, or additive manufactured high-performance parts. We offer you innovative solutions for nearly all ranges of size and requirements.

Using qualified advice when developing the product and with the state-of-the-art machinery in our tooling and additive manufacturing department we are always ready to realize your ideas. Therefore it is vitally important for us to maintain long-term customer relationships and to extend the range of high-quality products.

So we are always available for you in order to get to know your wishes and requirements to realize projects exactly according to your expectations. Maximum customer success is our ultimate goal.

EXPERIENCE FOR THE FUTURE

The Team behind your Solution

A wealth of knowledge and experience in the plastics industry, additive manufacturing and forward-looking business management are the keys for the implementation, transformation and realization of future-oriented technologies. For the fulfillment of your ideas, our competent experts support you at any time to bring your ideas to life.